V-OnePCB Printer

PCB prototyping made easy

Prototype and assemble PCBs in an hour and get immediate feedback on new designs.

Price: From $3,499.99 USD*

*Shipping and regional taxes not included

Drill sold separately

U.S. customers: Most Voltera products are made in Canada and are exempt from U.S. tariffs under USMCA trade agreement. Learn more

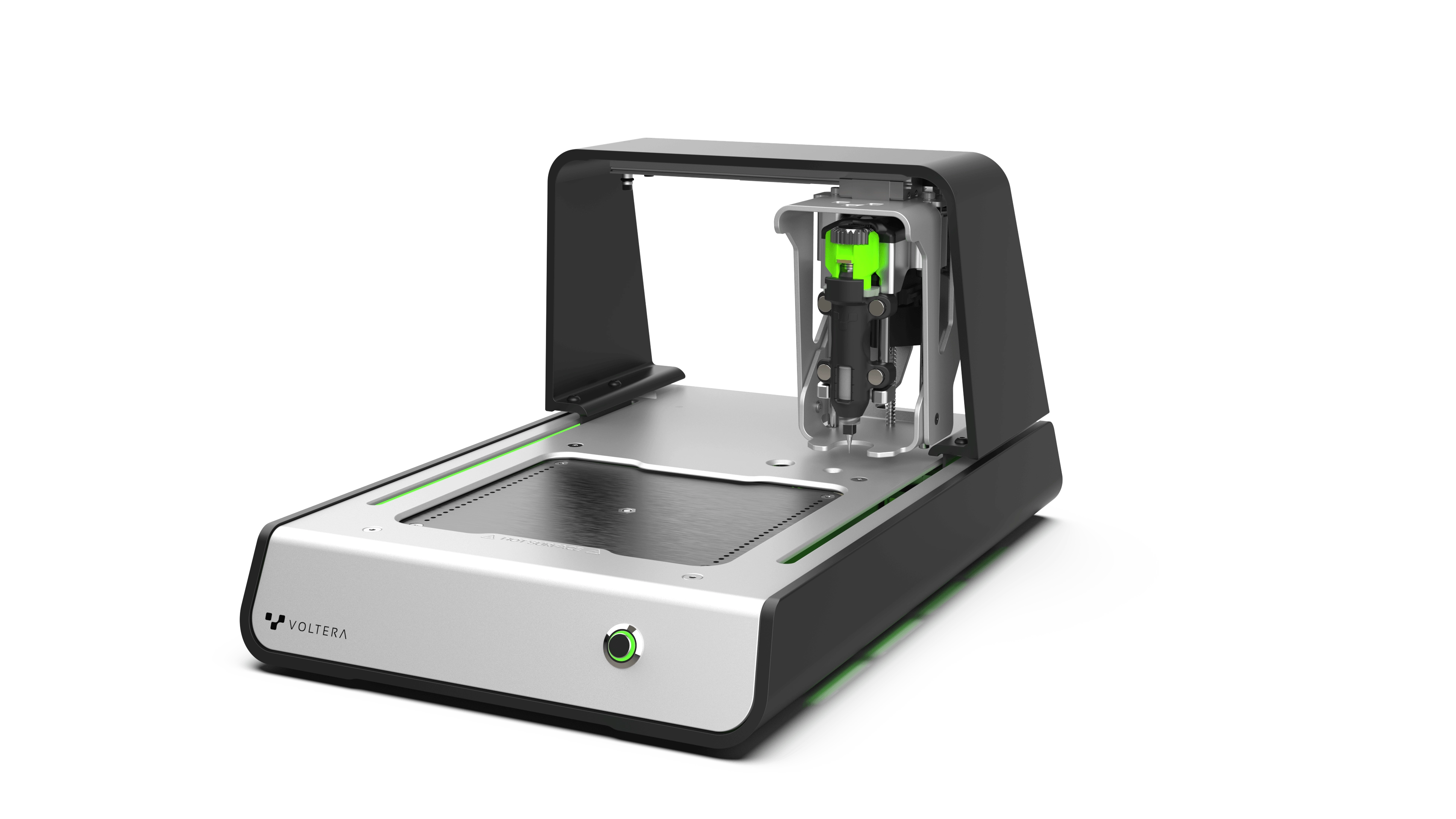

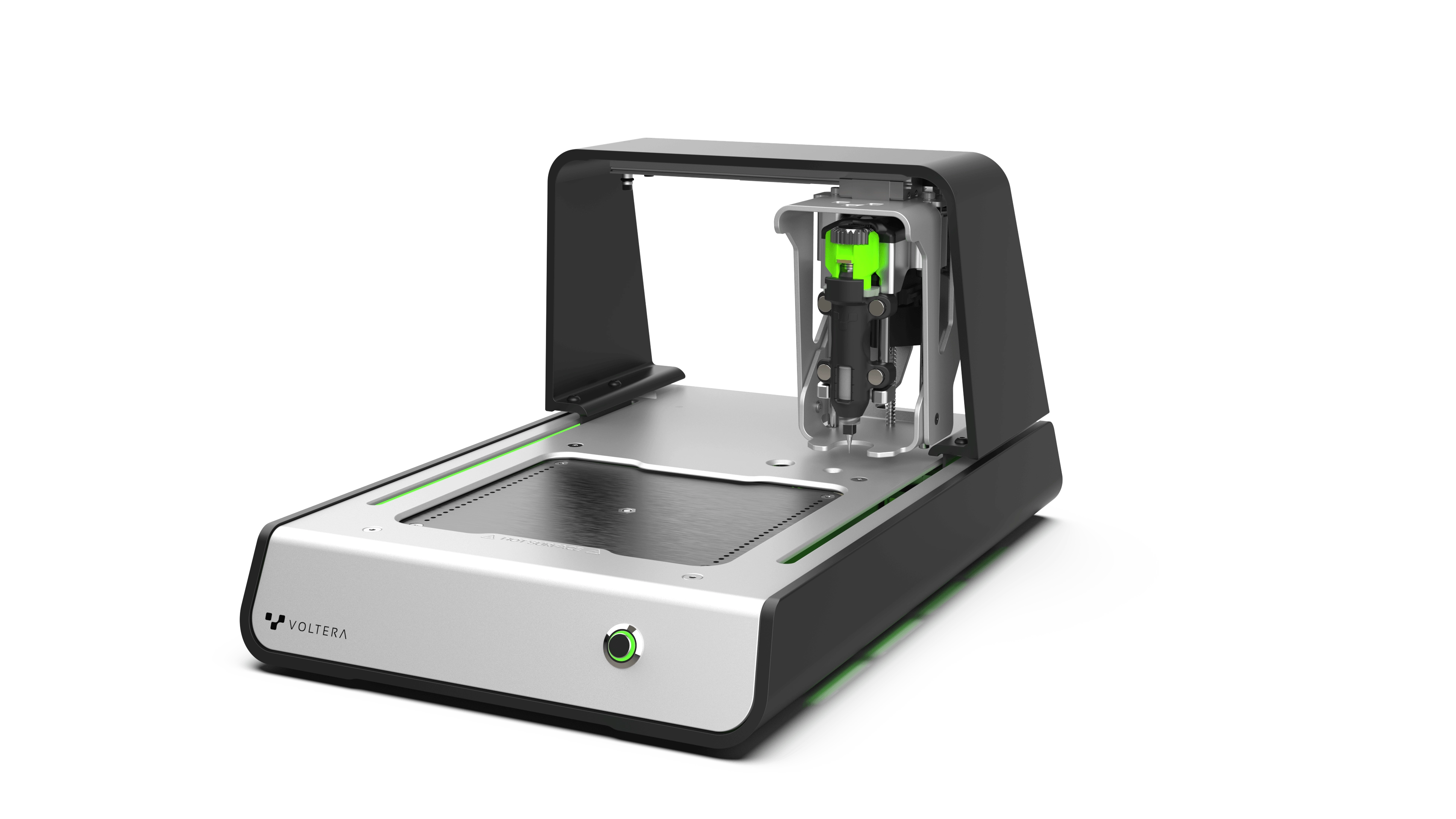

Meet V-One — A desktop circuit board printer

4-in-1 functionality

V-One has everything needed to prototype PCBs. It can drill through holes for vias, print traces, dispense solder paste, and reflow — all in one compact form factor.

Fast, low-volume prototyping

Iterate quickly and get immediate feedback on new designs. Print and assemble functional PCBs in an hour. Identify design errors early and reduce time to market.

Intuitive user experience

V-One is designed for all skill levels. From students in a classroom to electrical engineers in industry, V-One makes PCB prototyping easy at every stage of electrical development.

Intellectual property protection

Protecting patents, copyrights, and trademarks is important. Prototyping electronics with V-One means keeping intellectual property completely in-house.

V-One features overview

Circuit printing

Print conductive ink to create traces and pads.

Drilling

Drill holes for through-hole components and vias for two-layer PCBs.

Solder paste dispensing

Stencil-free solder paste improves solder joint quality over manual application.

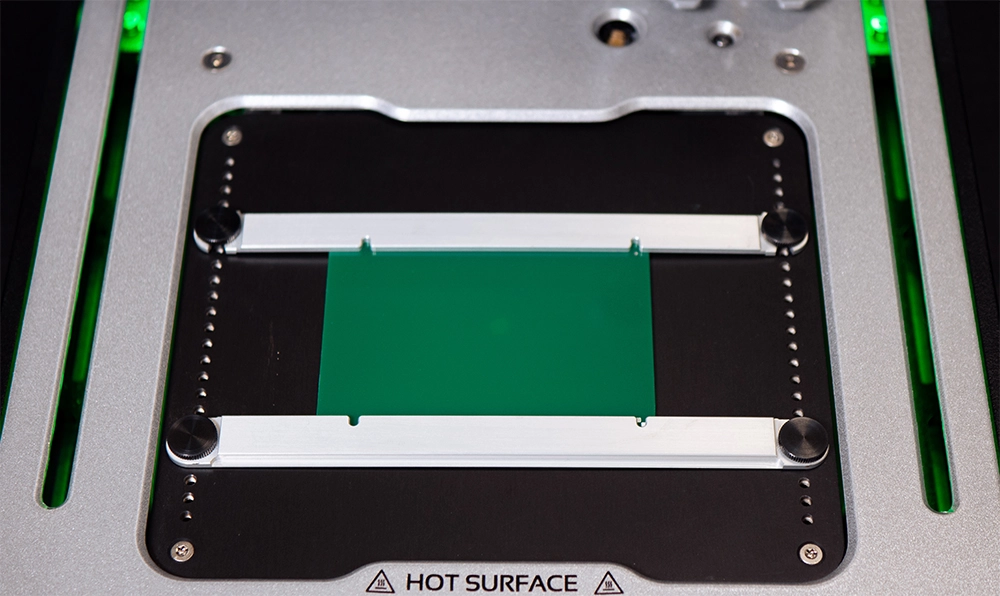

Built-in reflow

Reflow solder PCBs directly on the build area without a dedicated reflow oven.

Fast, hands-on, in-house PCB prototyping

Quicker development time

Iterate quickly and get immediate feedback on new designs.

IP protection

Protect your intellectual property by keeping your prototyping in-house instead of outsourcing it to vendors.

Hands-on learning

Engage students and young professionals with new opportunities to develop technical skills while bringing projects to life.

<1hr

Print time

4.5” x 5”

Print area

Double-sided

PCBs

Fast, hands-on, in-house PCB prototyping

Quicker development time

Iterate quickly and get immediate feedback on new designs.

IP protection

Protect your intellectual property by keeping your prototyping in-house instead of outsourcing it to vendors.

Hands-on learning

Engage students and young professionals with new opportunities to develop technical skills while bringing projects to life.

<1hr

Print time

4.5” x 5”

Print area

Double-sided

PCBs

Solder paste dispensing and built-in reflow

Stencil-free soldering

Dispense solder paste directly onto your printed circuit board (PCB) and leave expensive design-specific stencils behind. Say goodbye to stencil storage and cleanup!

Consistent soldering

Automatically dispense solder paste and correct unsatisfactory pads quickly with selective dispensing, eliminating hand soldering defects.

Reflow for PCB assembly

Reflow your PCB components with the built-in 550 W heater, which heats up to 240°C for up to 60 minutes — no ovens required.

Down to 0.5 mm

Pin pitch

240°C maximum

Reflow temperature

Solder paste dispensing and built-in reflow

Stencil-free soldering

Dispense solder paste directly onto your printed circuit board (PCB) and leave expensive design-specific stencils behind. Say goodbye to stencil storage and cleanup!

Consistent soldering

Automatically dispense solder paste and correct unsatisfactory pads quickly with selective dispensing, eliminating hand soldering defects.

Reflow for PCB assembly

Reflow your PCB components with the built-in 550 W heater, which heats up to 240°C for up to 60 minutes — no ovens required.

Down to 0.5 mm

Pin pitch

240°C maximum

Reflow temperature

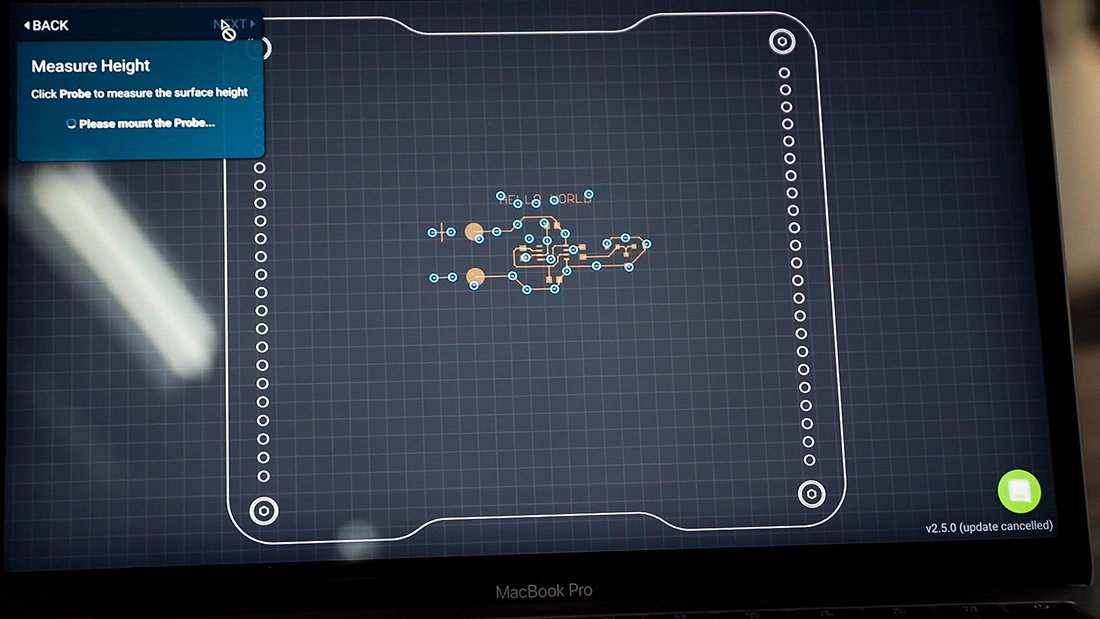

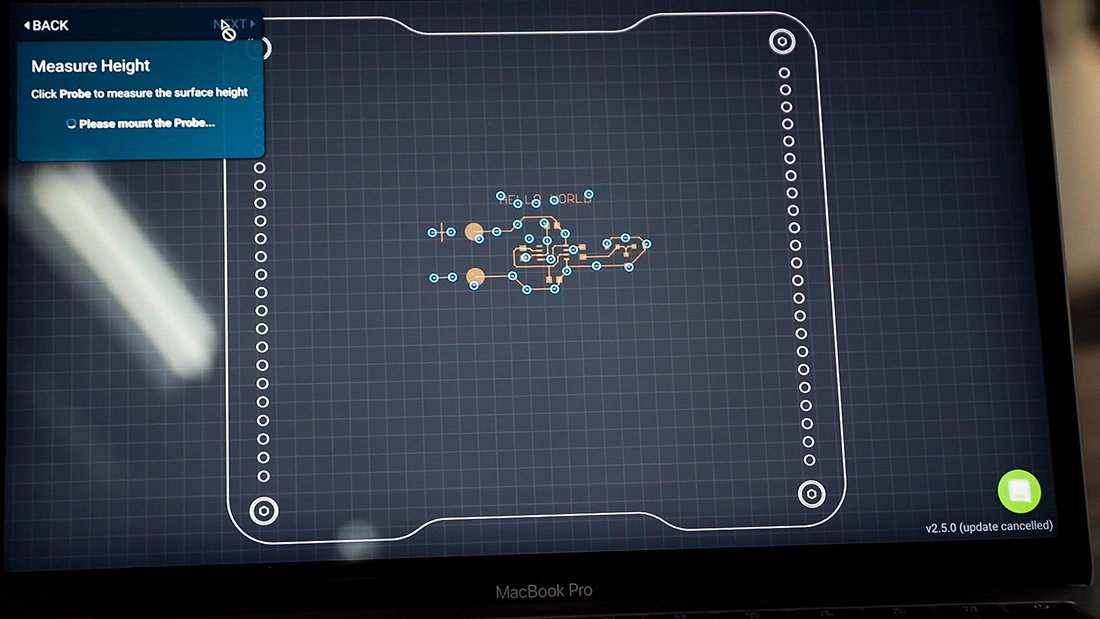

Intuitive user experience

Easy to use

Get hands-on with printing workflows and in-app help videos.

Use universal file formats

Upload Gerber files exported from any ECAD software, and the software will generate paths automatically.

Hassle-free updates

Learn about new capabilities and improvements with automatic software updates.

Gerber file compatible

Live, in-app chat

Intuitive user experience

Easy to use

Get hands-on with printing workflows and in-app help videos.

Use universal file formats

Upload Gerber files exported from any ECAD software, and the software will generate paths automatically.

Hassle-free updates

Learn about new capabilities and improvements with automatic software updates.

Gerber file compatible

Live, in-app chat

Simplify electronics projects

with pre-made design templates

Anatomy of V-One

Join thousands of V-One users

Customer stories

Want to learn more about the V-One?

Discover how people use V-One to rapidly prototype PCBs at their desks. This 4-in-1 additive manufacturing tool saves users time and money, and builds hardware faster.