Technical Specifications

Our dispensing systems for electronics prototyping

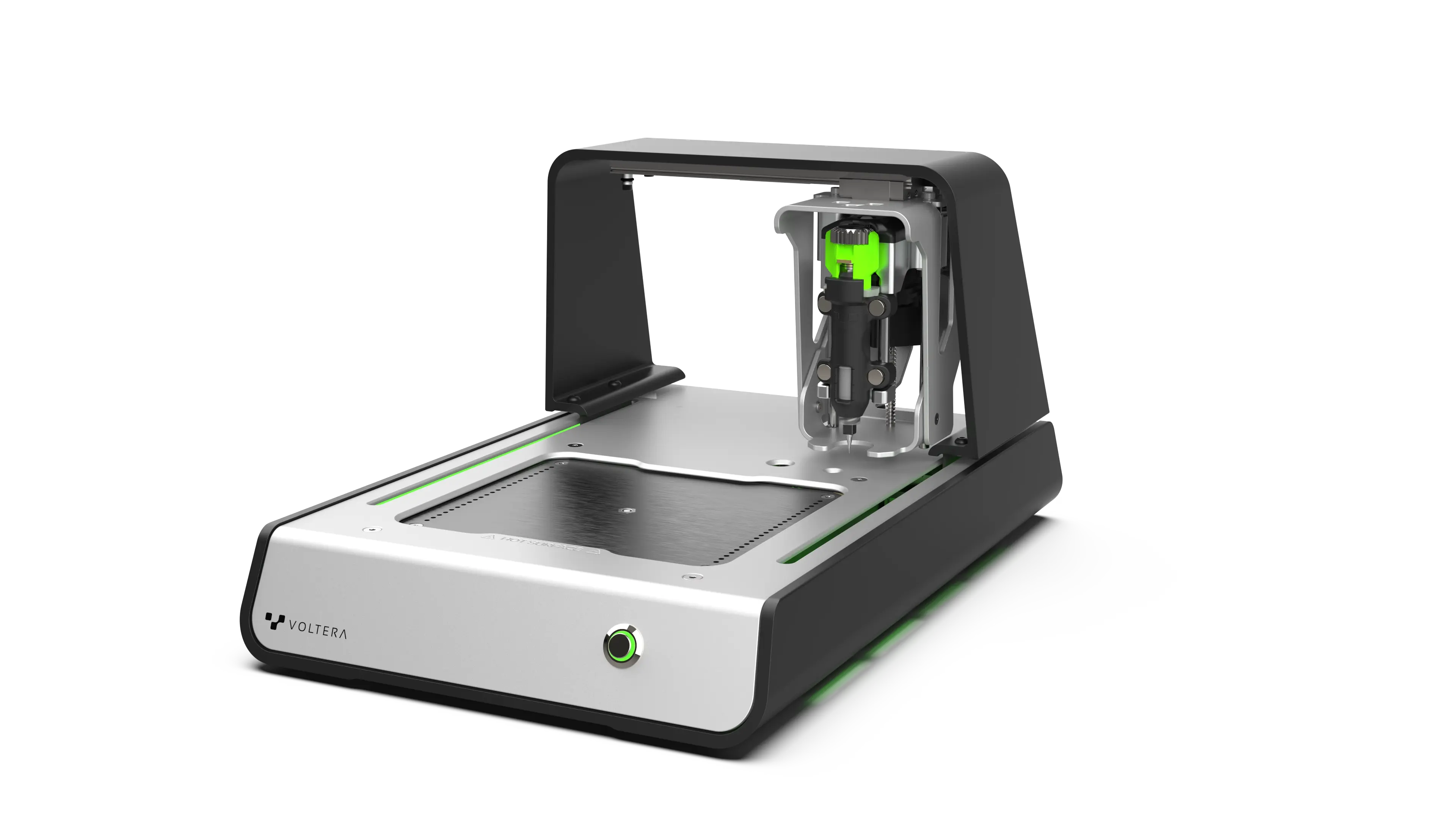

V-One

Turn your PCB design into a prototype in hours, not days.

Ideal for:

- ✓PCB prototyping

- ✓Hands-on learning

- ✓PCB assembly

- ✓Makerspaces

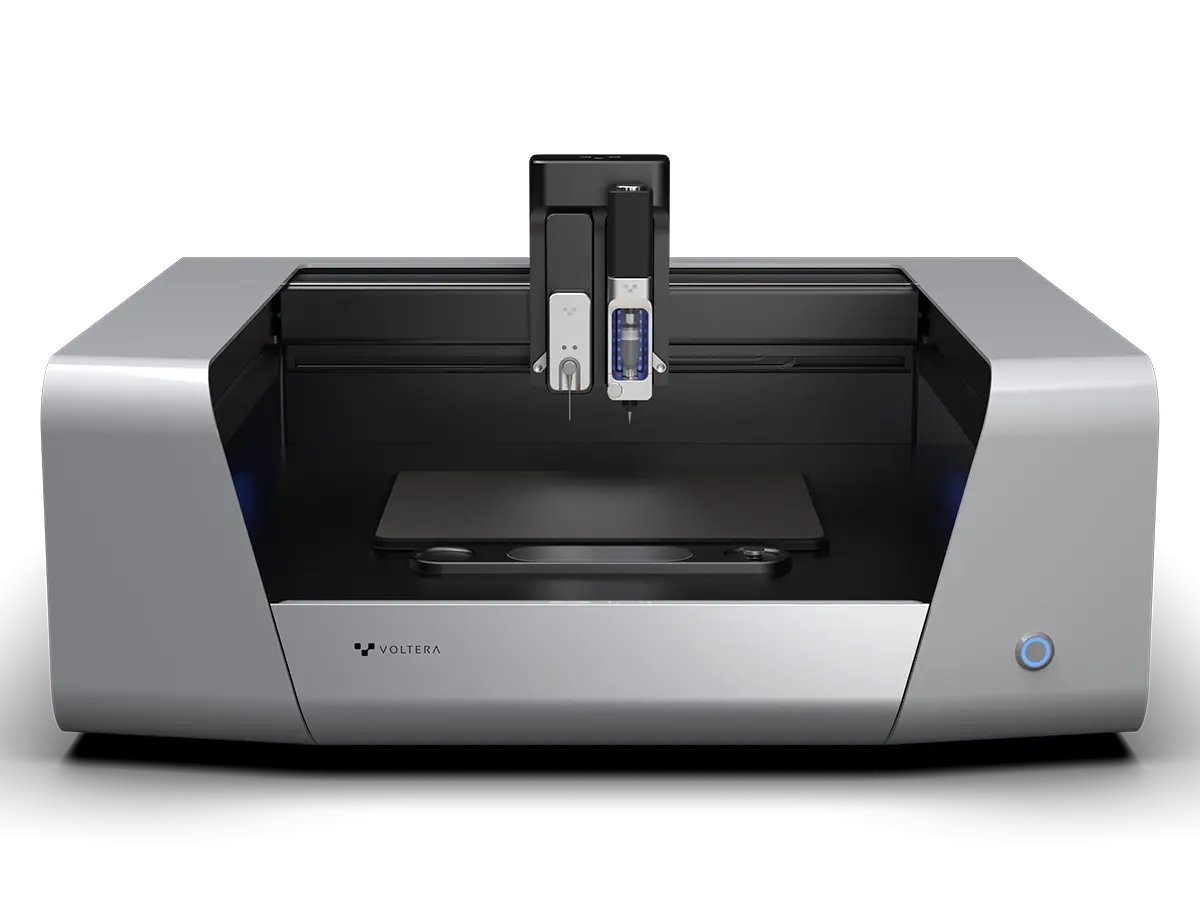

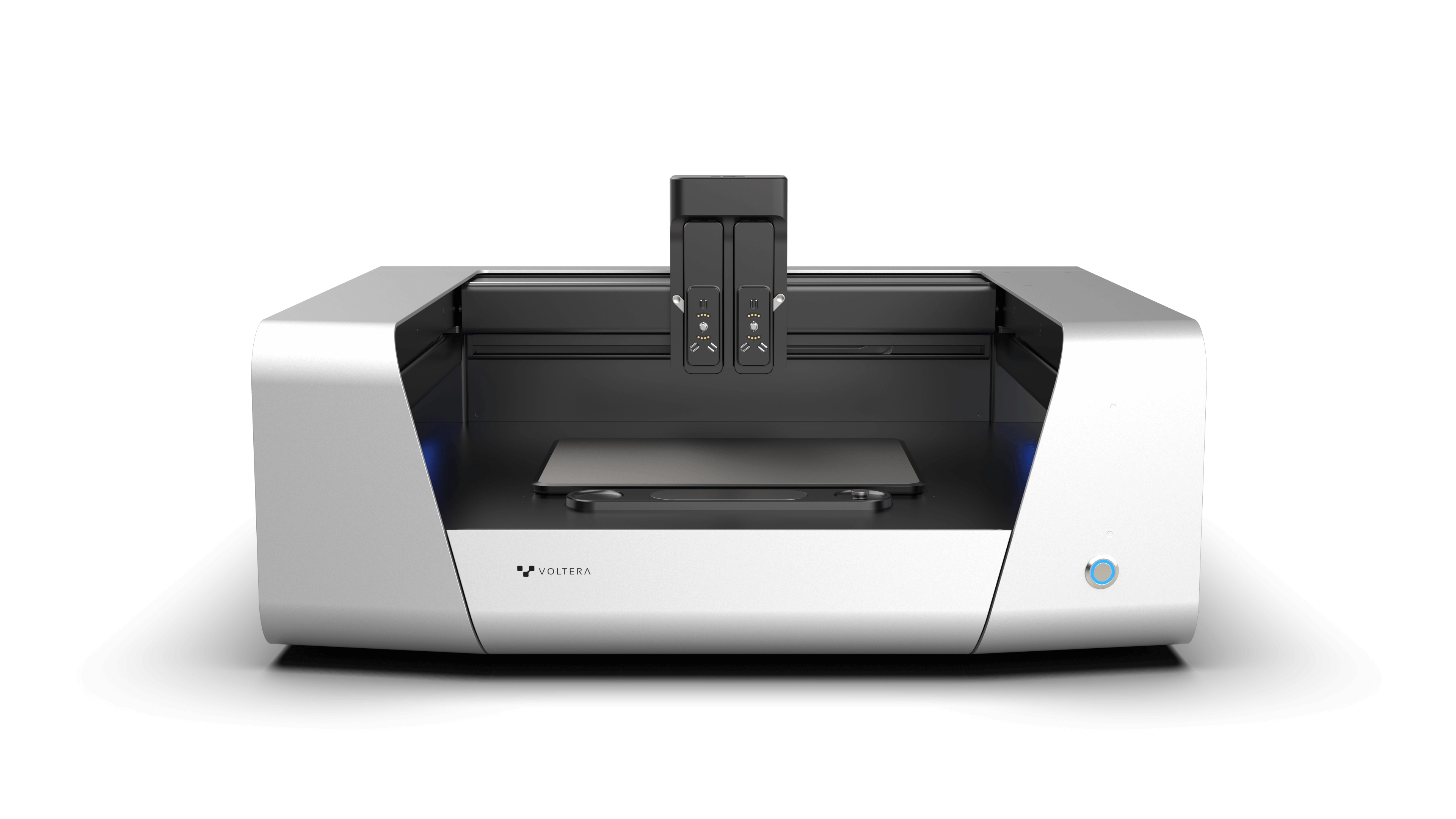

NOVA

Push the boundaries of what's possible in electronics and material science.

Ideal for:

- ✓Printed electronics R&D

- ✓Flexible and stretchable electronics

- ✓Microdispensing

- ✓Functional materials research

Specifications

Printer

- V-One

- NOVA

Dispensing technology

- Direct ink write (DIW)

- Direct ink write (DIW)

Pressure control

- Open loop

- Closed loop

Material temperature control

- -

- Up to 40°C

Minimum trace width

- 0.2 mm

- 0.1 mm*

Print area

- 128 mm x 116 mm x 3 mm

- 220 mm x 300 mm x 40 mm

XYZ resolution**

- 10 µm x 10 µm x 1 µm

- 2.5 µm x 7 µm x 1.25 µm

Layer capacity

- Double-sided PCBs

- Up to 4 stack-up layers***

Module slots

- 1

- 2

Compatible modules

- V-One Probe

- V-One Dispenser

- V-One Drill

- Smart Dispenser

- Smart Probe

- Vacuum Table

Substrate fixturing

- Clamping

- Elevated clamping

- Vacuum table

- Customizable (M5 threads, 40 mm grid)

Substrate thickness

- 1-3 mm

- Up to 30 mm****

Substrates

- Rigid: FR1 and FR4

- Rigid: PCBs, glass, ceramic, etc.

- Flexible: Polyimide, PET, etc.

- Stretchable: TPU, etc.

- Porous: Paper

Alignment and registration

- Manual

- Manual with camera assist (8 MP, 17 µm/px resolution)

Syringe capacity

- Up to 2 mL

- Up to 2.5 mL

Dispensable materials

- Solder paste

- Conductor 3

- Solder paste

- Conductive ink

- Other*****

Additional features

- Integrated hot plate for cure and reflow soldering

- Modular tool interface

- Dedicated priming area

- Tool and accessories drawer

- Solid state strain gauge tool setting

- Integrated vacuum pump

- Materials library

- Automatic fill level detection

- AI enabled vision system

* - Dependant on material properties and nozzle size

** - XYZ accuracy is +/- 20 µm

*** - Designs with more than 4 stack-up layers are achievable but depend on a number of factors. For more information, contact Support at support@voltera.io.

**** - Dependant on substrate fixturing height and nozzle length

***** - Contact sales to discuss application

Software

Interface

- Desktop application

- Browser-based web application

Operating systems

- Windows 7, 8, 10 (64bit)

- OSX 10.11+

File formats

- Gerber

- Gerber

- SVG (beta)

Hardware

Printer dimensions

- 390 mm × 257 mm × 207 mm

- 675 mm x 605 mm x 345 mm

Weight

- 7 kg

- 35 kg

Power requirements

- 100-120 VAC, 50/60 Hz, 575 W

- 200-240 VAC, 50/50 Hz, 575 W

- 100-240 VAC, 50/60 Hz, 221 W

Connectivity

- Wired USB 2.0

- 1 x USB-A 2.0

- 1 x USB-A 3.0

- Ethernet

- Wi-Fi******

****** - With use of included Wi-Fi dongle