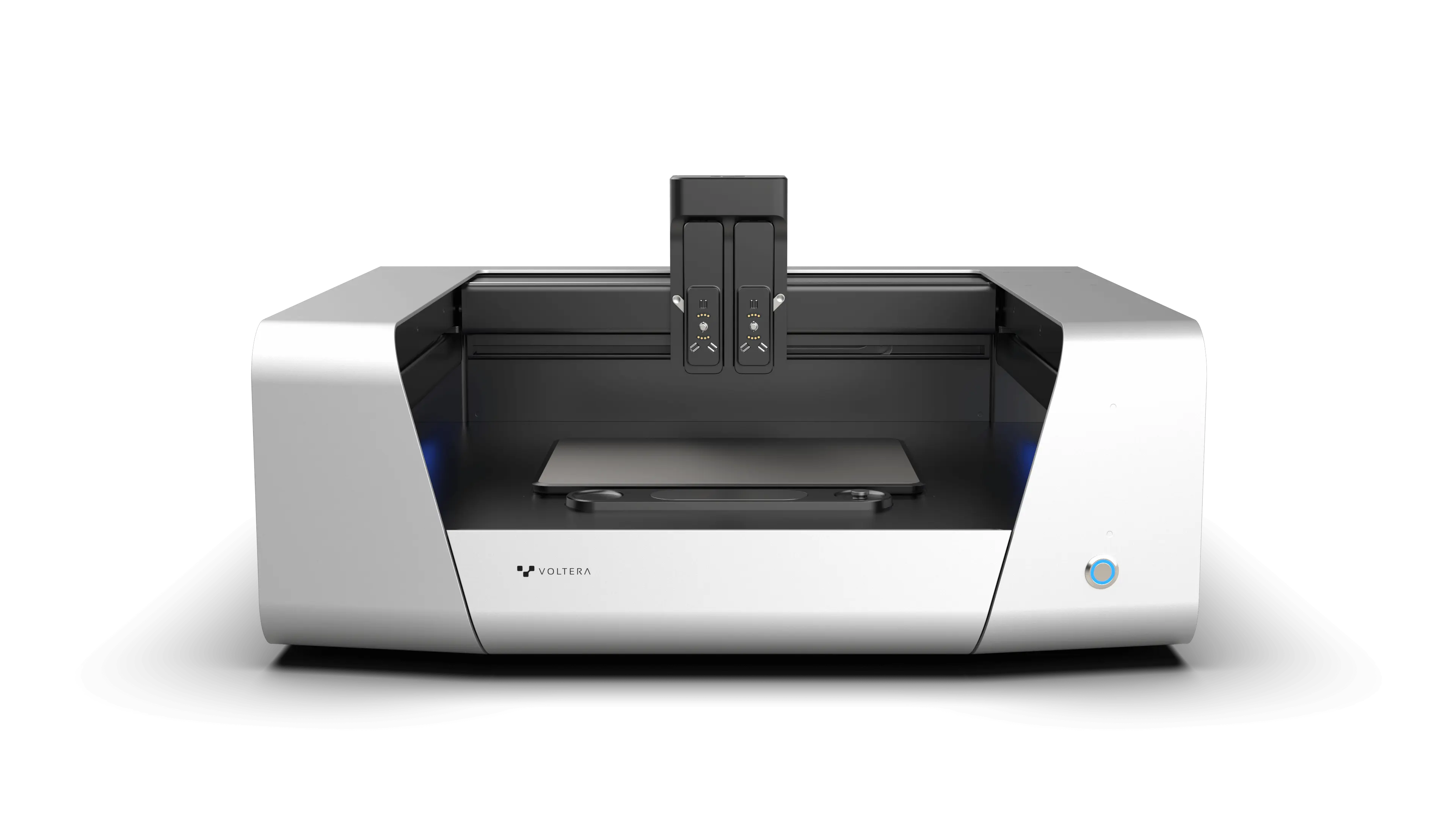

NOVA

The future of printed electronics

Unlock new opportunities and accelerate research and development with high-resolution printing using a range of functional materials and screen-printable inks.

Price: Contact sales to configure NOVA

U.S. customers: Most Voltera products are made in Canada and are exempt from U.S. tariffs under USMCA trade agreement. Learn more

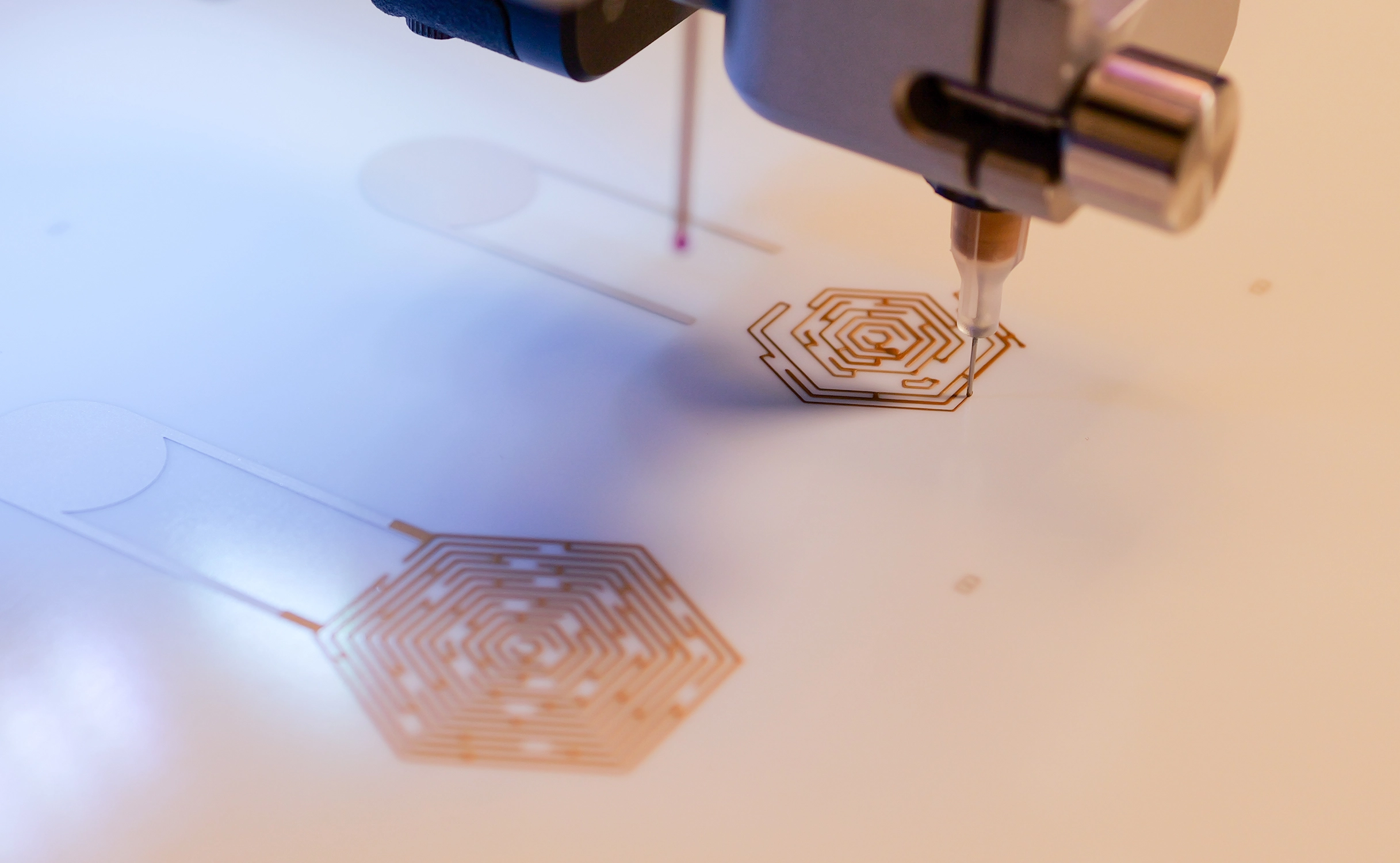

Meet NOVA — a materials dispensing system

Unlock new opportunities

Be first to explore what’s possible with printed electronics and push the limits of functional materials research and development.

Streamline research and development

Change designs on the fly and get immediate feedback on new ideas, accelerating R&D timelines and reducing costs.

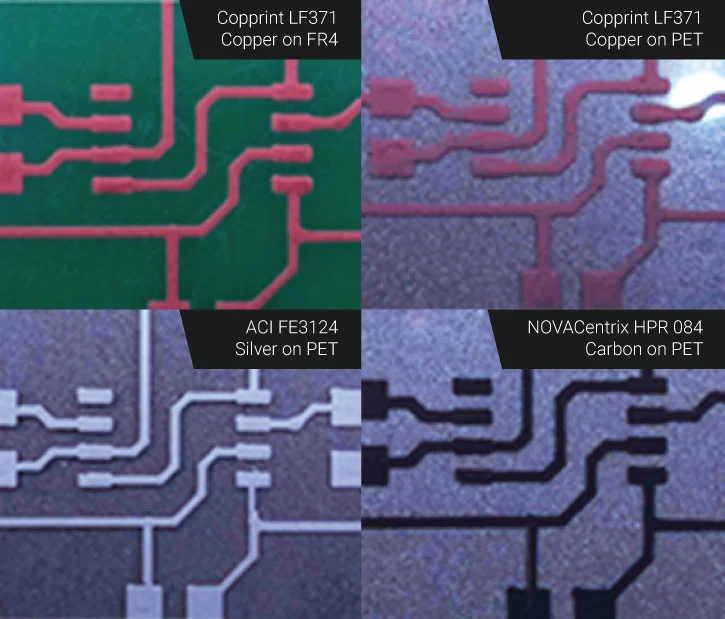

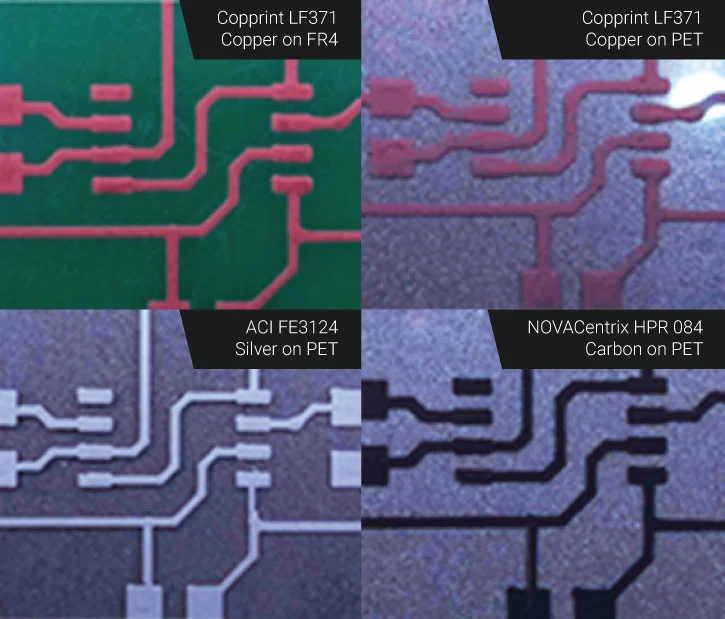

Total material freedom

Experiment with a wide range of substrates and screen-printable materials. Validate designs in the lab and seamlessly transition to production equipment.

No experience required

The intuitive user experience alleviates internal training challenges and allows anyone to achieve the results they are looking for.

What can NOVA do?

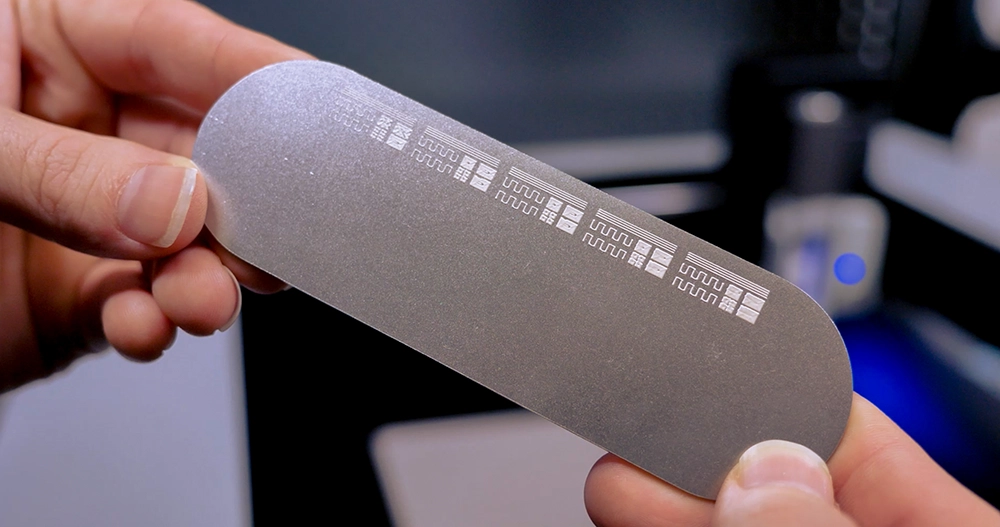

ECG electrodes

Materials and process:

Thermoplastic polyurethane (TPU)

Printed material

Creative materials EXP 2613-40 gold ink

Celanese Micromax™ Intexar™ PE874 stretchable silver paste

Nozzle size

Nordson EFD 7018395 200 µm dispensing tip

Nordson EFD 7018424 150 µm dispensing tip

Print time

23 minutes 57 seconds

ECG electrodes

Electroluminescent circuit

Magnesium zinc battery

Print on fabric

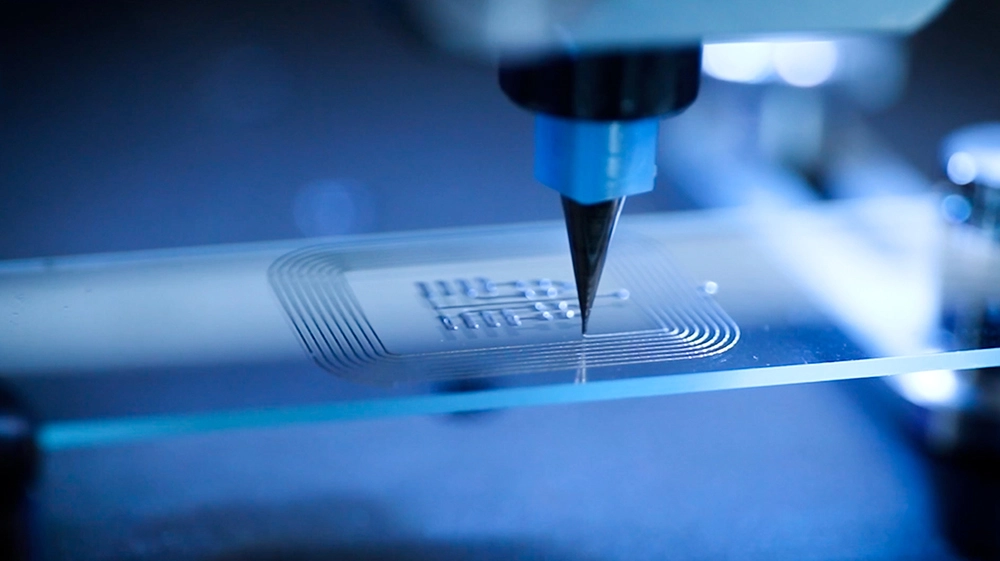

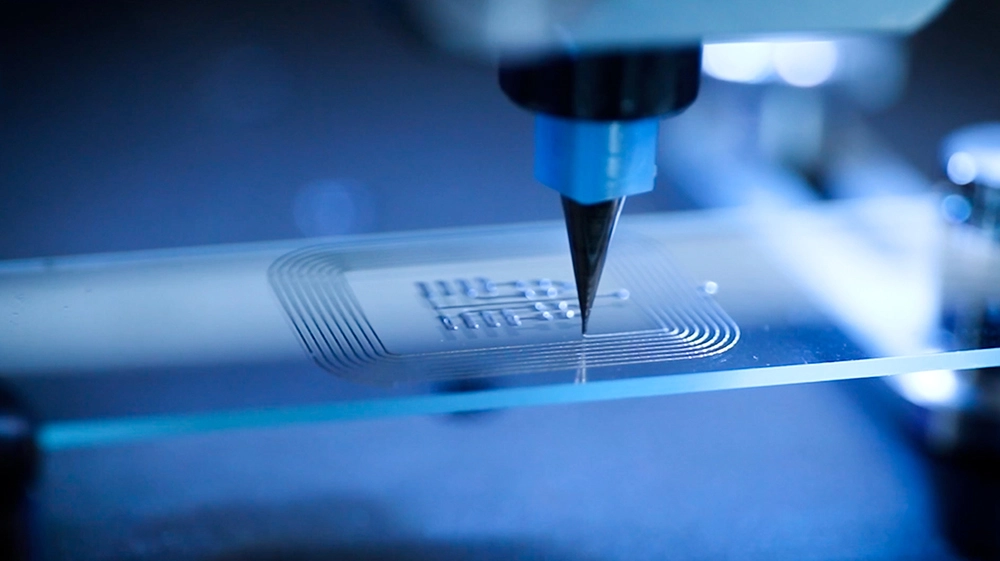

RFID tag

Flexible PCB

How many layers can NOVA print?

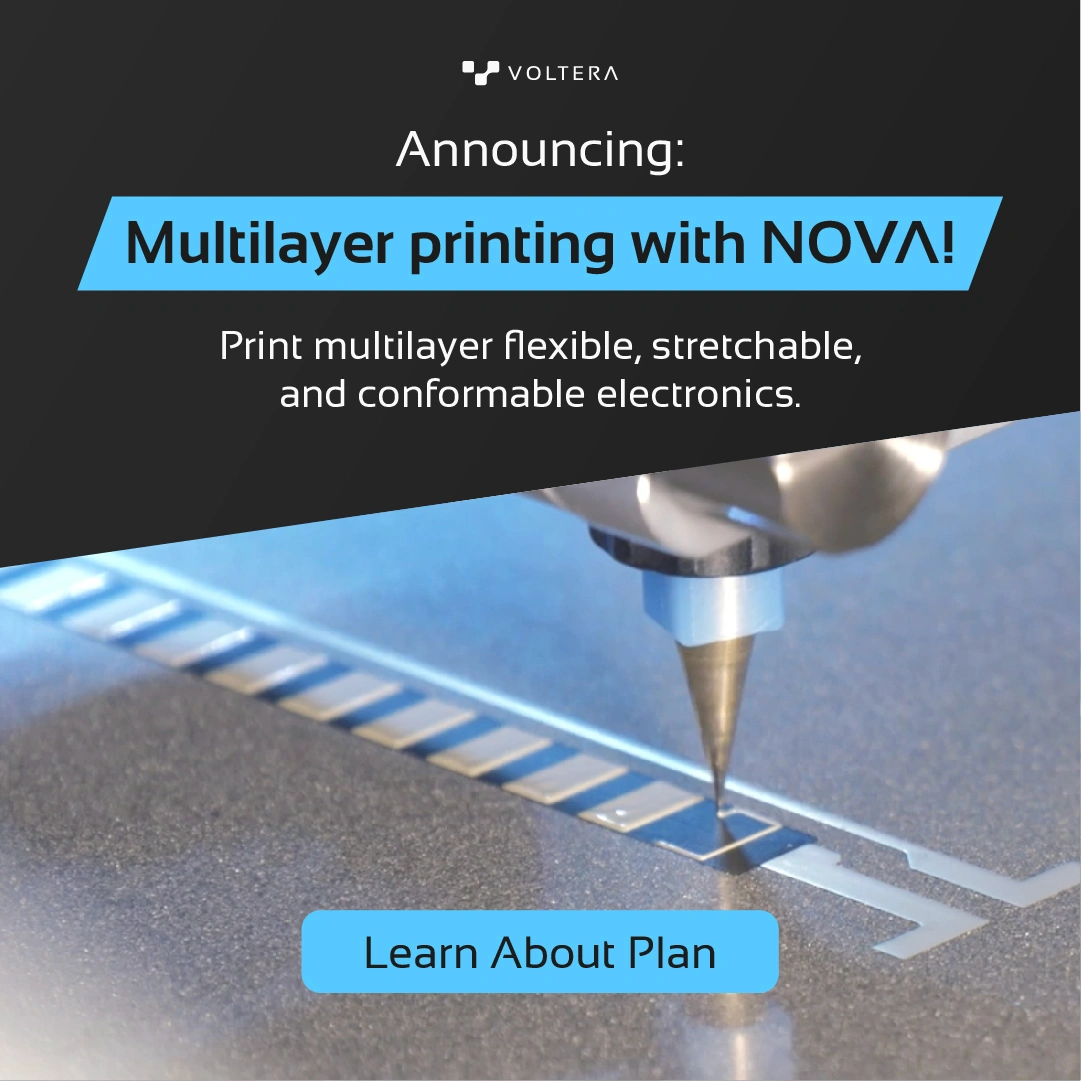

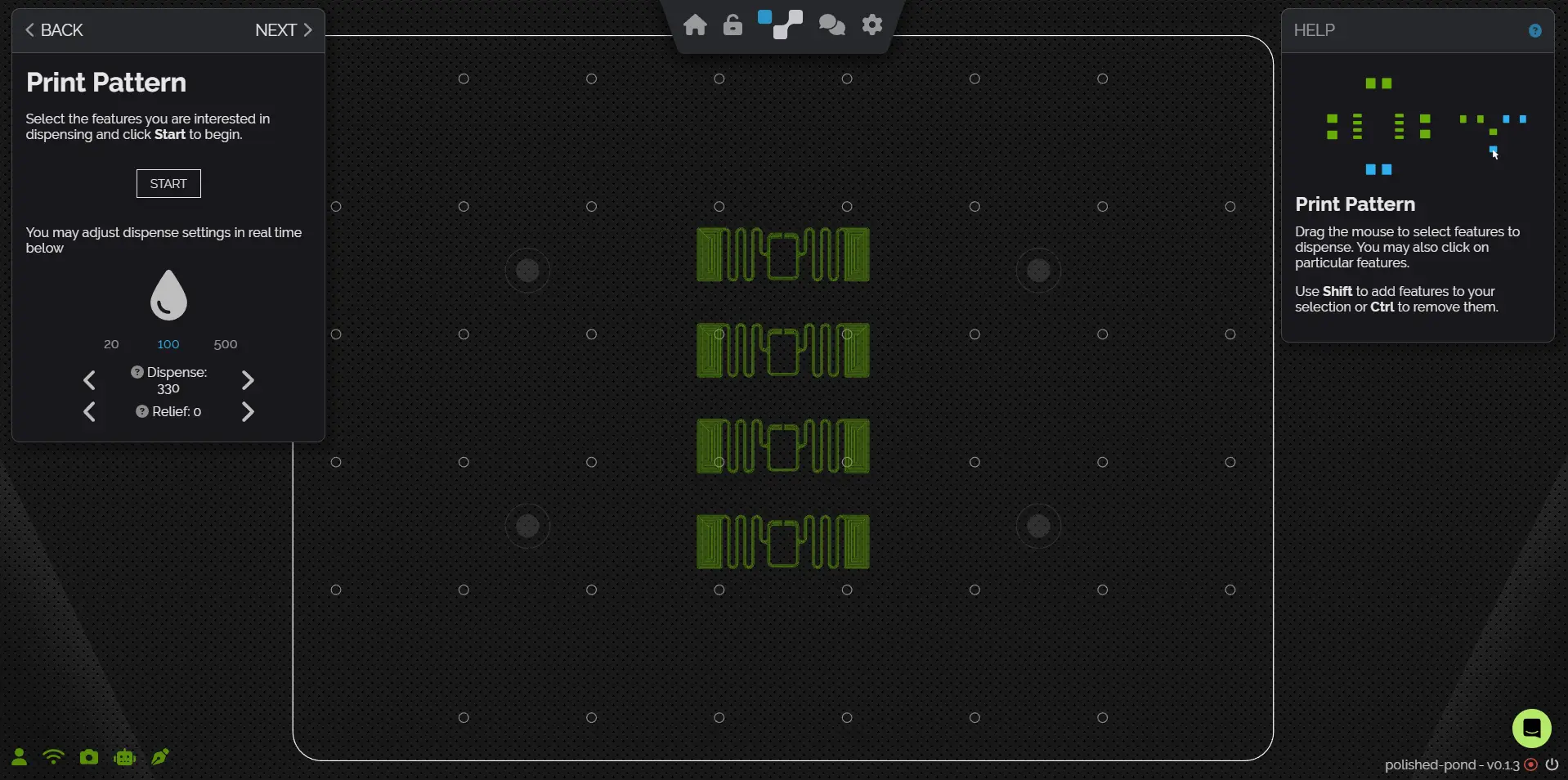

Meet Plan, NOVA’s newest feature*

Plan offers features such as multilayer printing and the ability to alter the sequence of trace printing.

With Plan, you can:

- Print up to 4 stack-up layers (multiple materials can be assigned to each layer)

- Print multi-material and multilayer designs

- Edit print jobs in a single workflow

- Minimize setup time for repeat print jobs

Meet Plan, NOVA’s newest feature*

Plan offers features such as multilayer printing and the ability to alter the sequence of trace printing.

With Plan, you can:

- Print up to 4 stack-up layers (multiple materials can be assigned to each layer)

- Print multi-material and multilayer designs

- Edit print jobs in a single workflow

- Minimize setup time for repeat print jobs

Printed sensors: University of Waterloo

“My research involves developing flexible and stretchable sensors for wearable electronics. With the Plan feature, I can separate different sensor elements, traces, or components to different layers and remove toolpaths that I don’t want. The ability to change the direction of tool paths has helped me the most — there’s no air pockets, and I have a very uniform trace width because I started printing in a designated safe region.”

Printed sensors: University of Waterloo

“My research involves developing flexible and stretchable sensors for wearable electronics. With the Plan feature, I can separate different sensor elements, traces, or components to different layers and remove toolpaths that I don’t want. The ability to change the direction of tool paths has helped me the most — there’s no air pockets, and I have a very uniform trace width because I started printing in a designated safe region.”

Need us to print your prototypes?

Submit your designs. We'll print them on NOVA and ship them to you.

NOVA benefits

Streamline research and development with direct-ink-write dispensing

No tooling

Change designs on the fly and iterate without screens or stencils, eliminating delays and reducing costs.

No waste

Print only what’s needed, conserving valuable material.

No cleanup

Material is contained throughout the printing process, simplifying cleaning and handling procedures.

90% faster

iteration time

96% reduced

material costs

Streamline research and development with direct-ink-write dispensing

No tooling

Change designs on the fly and iterate without screens or stencils, eliminating delays and reducing costs.

No waste

Print only what’s needed, conserving valuable material.

No cleanup

Material is contained throughout the printing process, simplifying cleaning and handling procedures.

90% faster

iteration time

96% reduced

material costs

Explore new possibilities with high resolution, closed-loop dispensing

Increased material options

A wide range of compatible viscosities unlocks enhanced performance and material characteristics, from inks to gels and pastes.

Reduced risk

Validate designs and materials in the lab and seamlessly transition into production with scalable printing technologies.

Repeatable results

Achieve repeatable results with close-loop pressure feedback, temp-controlled dispensing, and an optimized algorithm for multilayer printing.

100 µm

Line width*

1,000 - 1,000,000 cps

Viscosity range

Up to 4

Stack-up layers**

* Dependent on material and nozzle.

**More stack-up layers are possible under certain conditions.

Explore new possibilities with high resolution, closed-loop dispensing

Increased material options

A wide range of compatible viscosities unlocks enhanced performance and material characteristics, from inks to gels and pastes.

Reduced risk

Validate designs and materials in the lab and seamlessly transition into production with scalable printing technologies.

Repeatable results

Achieve repeatable results with close-loop pressure feedback, temp-controlled dispensing, and an optimized algorithm for multilayer printing.

100 µm

Line width*

1,000 - 1,000,000 cps

Viscosity range

Up to 4

Stack-up layers**

* Dependent on material and nozzle.

**More stack-up layers are possible under certain conditions.

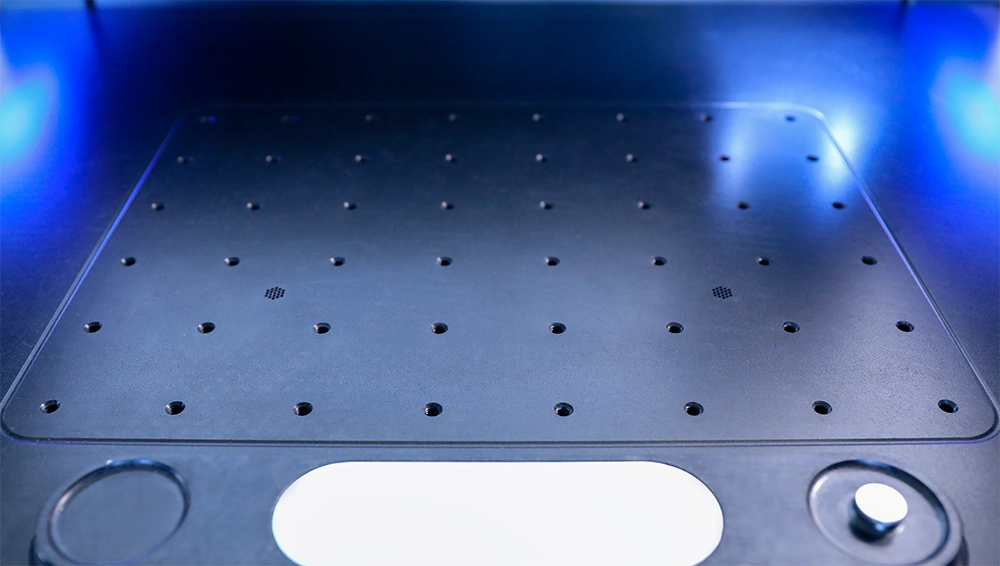

Adapt to any application with a large, configurable print area

Rigid substrates

Secure your rigid substrates of all shapes and sizes with provided threads onto the 40 mm x 40 mm mounting grid.

Compliant substrates

Secure your conformable substrates with NOVA’s porous titanium vacuum table which applies uniform suction.

Unconventional substrates

Develop application-specific fixturing for unconventional substrates using the mounting grid features.

220 mm x 300 mm

Print area

40 mm x 40 mm, M5

Mounting grid

Adapt to any application with a large, configurable print area

Rigid substrates

Secure your rigid substrates of all shapes and sizes with provided threads onto the 40 mm x 40 mm mounting grid.

Compliant substrates

Secure your conformable substrates with NOVA’s porous titanium vacuum table which applies uniform suction.

Unconventional substrates

Develop application-specific fixturing for unconventional substrates using the mounting grid features.

220 mm x 300 mm

Print area

40 mm x 40 mm, M5

Mounting grid

Ensure print accuracy with integrated computer vision

Eliminate registration errors

Accurately position and align patterns with augmented reality overlay.

Optimize print quality

Find the ideal height, pressure, and print settings with a dedicated material calibration workflow.

Simplify reporting

Capture images for analysis, measurements, and documentation.

17 µm/pixel

Resolution*

1920 x 1080

Image size

* Dependent on substrate height

Ensure print accuracy with integrated computer vision

Eliminate registration errors

Accurately position and align patterns with augmented reality overlay.

Optimize print quality

Find the ideal height, pressure, and print settings with a dedicated material calibration workflow.

Simplify reporting

Capture images for analysis, measurements, and documentation.

17 µm/pixel

Resolution*

1920 x 1080

Image size

* Dependent on substrate height

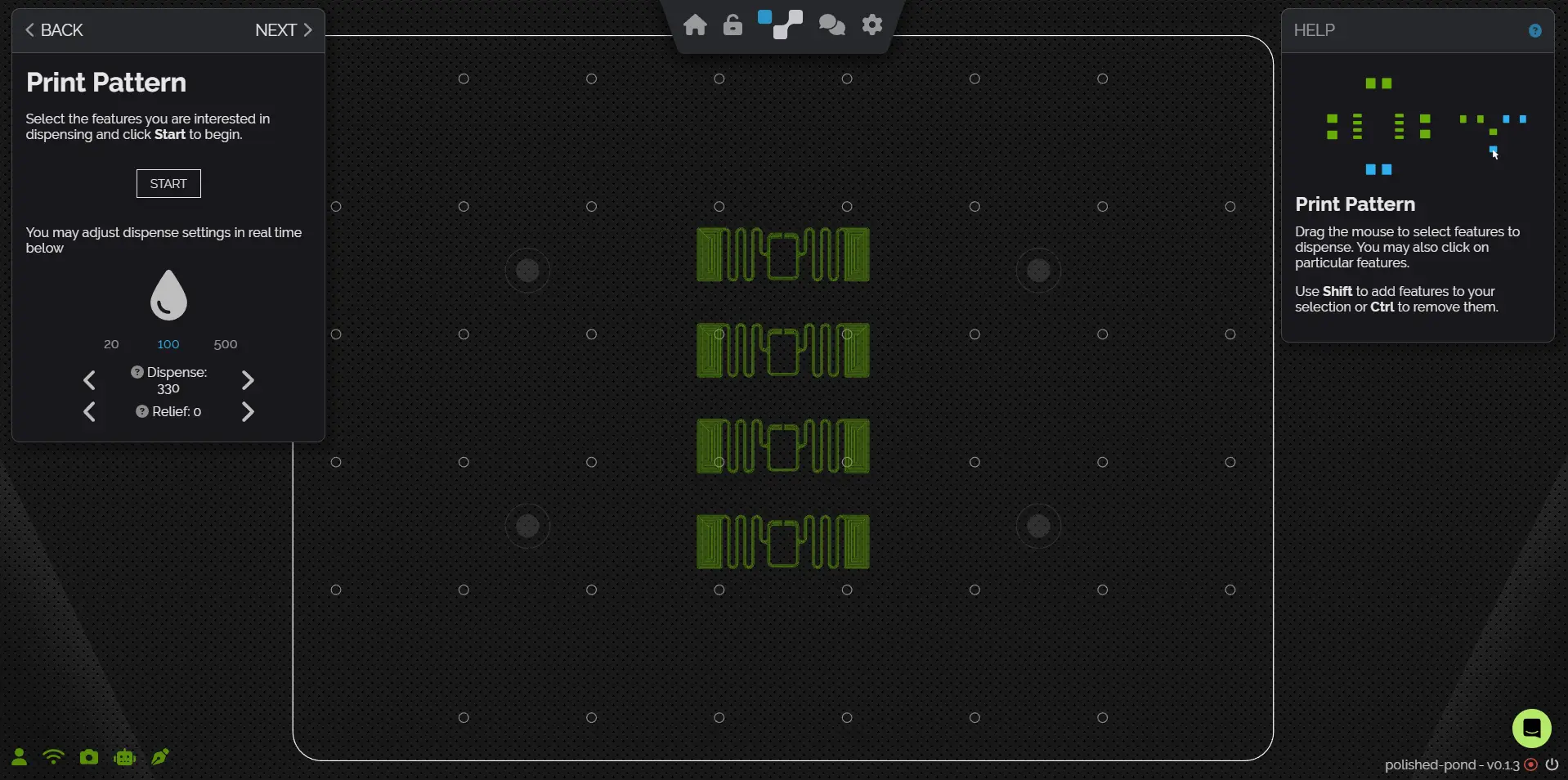

Easy-to-use software

Smooth onboarding

Guided workflows, walk-through videos, and user profiles in the browser-based app set you up for success.

Seamless cooperation and independent research

Browse, create, and modify saved profiles for materials and substrates with the central materials library.

In-app access to support

Connect directly with Voltera support via live, in-app chat.

No downloads required

Gerber file compatible

Easy-to-use software

Smooth onboarding

Guided workflows, walk-through videos, and user profiles in the browser-based app set you up for success.

Seamless cooperation and independent research

Browse, create, and modify saved profiles for materials and substrates with the central materials library.

In-app access to support

Connect directly with Voltera support via live, in-app chat.

No downloads required

Gerber file compatible

NOVA anatomy

Who's using NOVA

Want to see NOVA in action?

NOVA will help bridge the gap between what you can do and what you wish you could do with electronics. Take a look at how people are using NOVA for rapid prototyping of additive electronic devices and to print electronics on everything.